The payback game: so just which hydraulic manufacturers will profit from the robot challenge?

The FT recently reported that China bought 66,000 out of 240,000 robot units sold globally last year. The UK bought only an estimated 2400 units in 2015, according to statistics from the International Federation of Robotics. It makes riveting reading: China’s technological transformation still has far to go — the country has just 36 robots per 10,000 manufacturing workers, compared with 292 in Germany, 314 in Japan and 478 in South Korea. But it is already changing the face of the global manufacturing industry. With 70% of the global robot sales spread across five countries (China, Japan, the United States, the Republic of Korea and Germany) it’s the Chinese ambitions for a robot workforce that go much further and Sarum Hydraulics is taking note.

In China, humans are already installing robots that will ultimately take their jobs as the first robot-only factory is being built in China’s Dongguan factory city. The factory, owned by Sehnzhen Evenwin Precision Technology, aims to reduce the current workforce of 1,800 by 90%.Since September last year, a total of 505 factories across Dongguan have invested 4.2bn yuan (£430m) in robots, aiming to replace more than 30,000 workers, according to the Dongguan Economy and Information Technology Bureau.

At Sarum we are fascinated to see where robots will find applications in smaller UK manufacturing businesses. Boston Consulting Group predicts that by 2025, up to a quarter of jobs will be replaced by either smart software or robots, while a study from Oxford University has suggested that 35% of existing UK jobs are threatened by automation in the next 20 years. If true, the debate about whether machines will eliminate the need for human employment is no longer just academic. Robots are going to be here in almost every factory.

The question for Sarum Hydraulics is whether we can really see robots assembling pumps better than our skilled labour. Or working alongside a human? Look across to big players in China and Foxconn, maker of electronic devices such as Apple’s iPhone, plans a robot workforce although its ambitions are slightly more modest – aiming for 30% of production performed by robots in the next five years. So should UK and European hydraulic manufacturers be excited about their robotic future or fear relentless cost cutting from highly automated competitors who have made that investment?

China will undoubtedly power ahead with its own automation revolution that within a few years will make it the biggest user of robots in the world. That will very probably keep low cost plants rooted in China and cut the trend for assembly work to move to ever lower cost countries in the developing world. Their workforces would then miss out on the manual labour route out of poverty which has been so significant in lots of countries. It may well also keep China in its place as the workshop of the world for many more years. The FT observes that the Chinese are currently buying robots from elsewhere but will inevitably develop their own expertise, to become a power house of robot manufacturing in years to come.

So with the inexorable rise of robots, what transformation in manufacturing can we expect and how should businesses respond? The answer probably depends on who you are. The building site of the future is going to look very different to the one we are all used to today. Instead of men in high-viz jackets and hard hats, there are going to be drones buzzing overhead, robotic bulldozers and 3D printers churning out new structures.

Move to manufacturing and you cover such a wide spectrum that you cannot generalise. Coming closer to home, Sarum thinks hydraulic manufacturers should not get fixated with robots only finding a place in “big numbers.” We know of one UK valve manufacturer, running small batch production, that is buying its first robot simply to make an awkward operation repeatable and accurate. So keep an open mind, look at what you make and how many, the processes involved – and just think laterally.

Conversely, we know the Chinese love volume and so many global manufacturers have migrated to a worldwide range of products made in massive quantities in China or other offshore manufacturing centres. So if you are still in business producing large quantities, mainly by humans, you run the risk of being overtaken by highly automated plants and a cleverly designed product optimised for automated assembly. And bingo, you’re out of business.

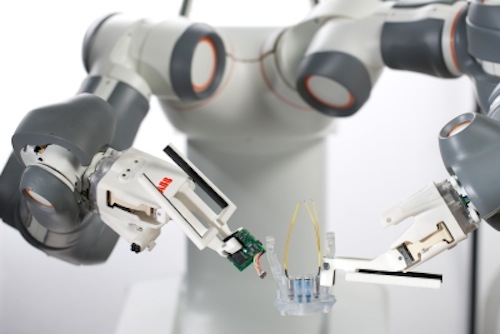

Robotic assembly line. Image credit – http://www.ifr.org/index.php?id=59&df=ABB_Fabrikautomation.jpg

At Sarum Hydraulics we’ve already clocked the fact that some European countries are massively into automation. Try to buy a non-standard ball valve from Italy and you find that in order to fight the far Eastern challenge, their manufacturers are highly automated. The standard valve is the only one available, as batch numbers are enormous. The French too, are impressively automated, perhaps in response to complicated labour laws as well as fighting international competition.

With traditional automation, sophisticated safety guarding is the order of the day, with stop switches and light curtains to cut the risk of injury. In the future, when a robot is clever enough to sense when anybody gets too close to it, this will open up a whole new world – and no doubt help small businesses live every day with some robots in the workforce. According to Google’s Director of Engineering, Ray Kurzweil, we’ve only 13 years until computers become more intelligent than humans. The entrepreneur and futurologist predicts that by 2029, computers will be able to understand what we say, learn from experience, make jokes, tell stories – and even flirt.

Back to basics for now, for a small or medium sized UK batch hydraulic manufacturer, making 25’s, 50’s or 100’s – where does this leave you? The traditional view is that if you are only making 50 odd batches, it’s not worth setting up to automate an assembly process. Maybe not for much longer. At Sarum Hydraulics we just wonder what would tip the balance in favour of robotics – and a cheap Chinese robot might just make the difference.

One vital question to consider is who is the tech guru in your company – the employee with first class IT skills and a hands-on ability to programme the robot? Buying a robot is one thing. But you also need someone who really understands the manufacturing process to achieve results. Couple this with the on-going skills shortage in the engineering industry, where we’re told that 50% of the entire workforce is due to retire by 2020. How are we going to fill new engineering roles, if nobody has the skills – or conversely, if your business offers a niche engineering product not compatible with automation and robotics? It’s all up for debate. At Sarum HQ, we’re all buoyed up by the robotic era and we’re working hard with an open mind, to embrace the robot challenge head on.

For years, people have used our Sarum Hydraulics Micropac hand pumps and pressure test equipment for all manner of fluids and operating conditions. Talk to us on +44 (0)1722 328388, look at www.sarum-hydraulics.co.uk or buy direct on www.pumpshoppro.com .

Good read.

For more NEWS

This was a very good info about hydraulics and how it can used for the advancement of Robotic Arm