Tech helps in fighting the hydraulic contamination battle.

If anybody tells Sarum Hydraulics that there is a “contamination issue”, we insist on digging deeper. Maybe that was an acceptable blanket excuse in 1986, but not today.

We just need to know what it is. We had an “old school” optical microscope for years, a cheap USB ‘scope a few years ago (commendable for such a cheap device) but now we have invested in a 1 micron resolution wireless unit. It connects to your i-pad in seconds, look at your image and grab a shot or video. Wonderful!

Get a sample of the contamination onto a clean room wipe then onto a microscope slide and under our trusty ioLight wireless microscope. The images or videos are there on your iPad without the fiddling.

Here are the bad boys that we suggest you look out for in hydraulic contamination.

Our favourite 6 culprits:

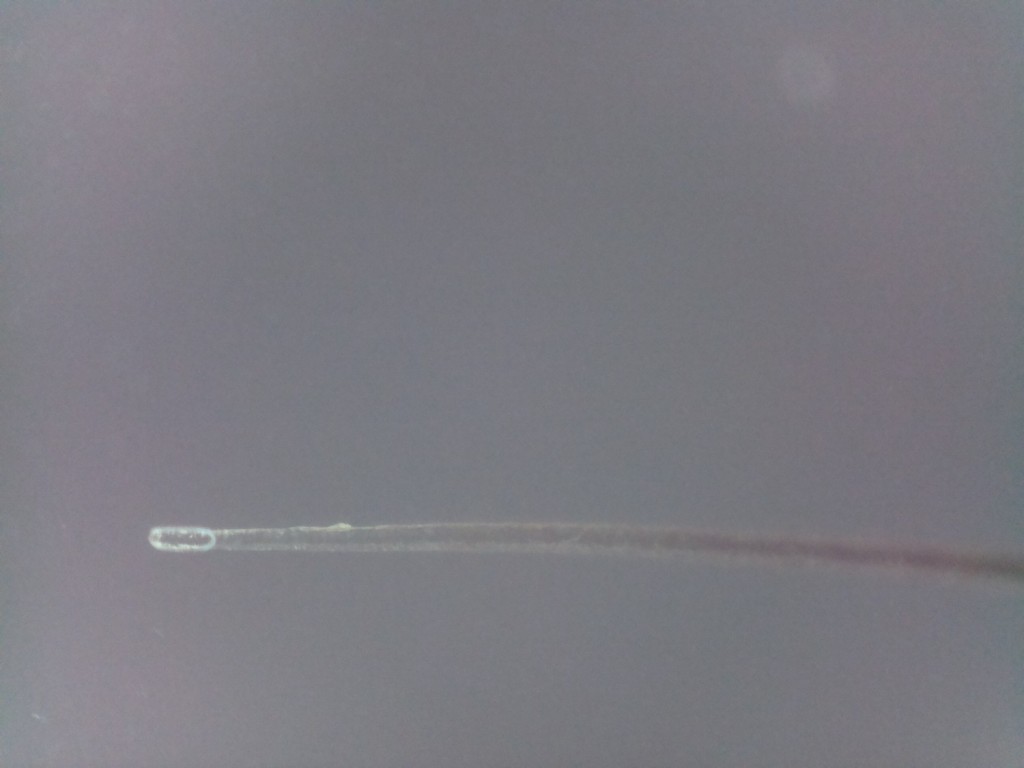

1. A whisker with very fine ends. Our experience point to fine whiskers that can be generated from threads as they are screwed together. This is really not good. But is this inevitable even here and there? Does this suggest that everything should be flushed?

This is an occupational hazard in hydraulics but life need not be difficult. Gauging machined threads is a must. A good machinist won’t burr over the screw cut thread with a chamfering tool and won’t leave a whisker where the thread runs out into an undercut. Is thermal deburring the best investment you can make?

Yes, we think so. Talk to Paddy House at the Deburring Centre and you will be a believer as well.

Figure 1- Fine Whisker from Thread

Figure 1- Fine Whisker from Thread

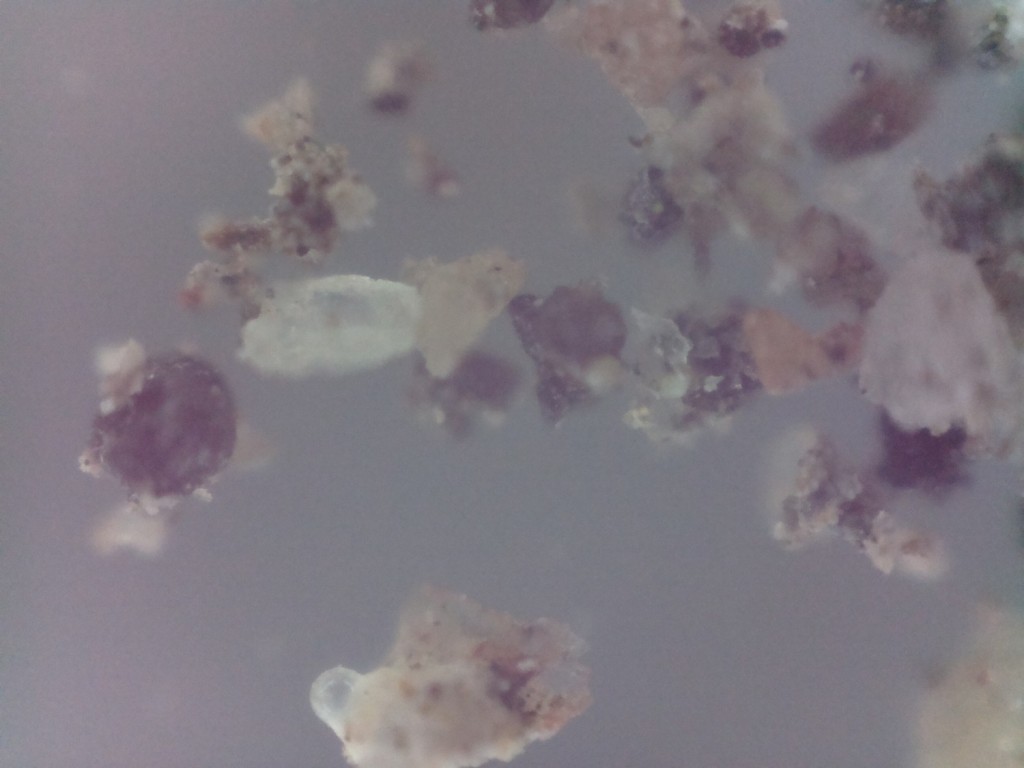

2. Glassy granules. If you have issues with glassy “rocks” blocking up an orifice, we would wager somebody has dropped a part and picked up silica particles from the workshop floor.

A possibility is sand from a sand casting still lurking. These particles are very distinctive and tell a story, if people will admit to them. This is very tiresome.

Figure 2- Glassy Granules

Figure 2- Glassy Granules

3. Whiskers of constant diameter. Hairs are very distinctive once you know what to look for. You may even be lucky and see the hair follicle on the end. Eyebrows can be a big source of contamination.

Figure 3- Hair Follicle

Figure 3- Hair Follicle

4. A mush of fibres. If under the ioLight, the fibres look like straw, think cardboard or if they look finer, think paper towel. Although colours are difficult, a brown tinge would suggest cardboard.

Figure 4- Cardboard Fibres

Figure 4- Cardboard Fibres

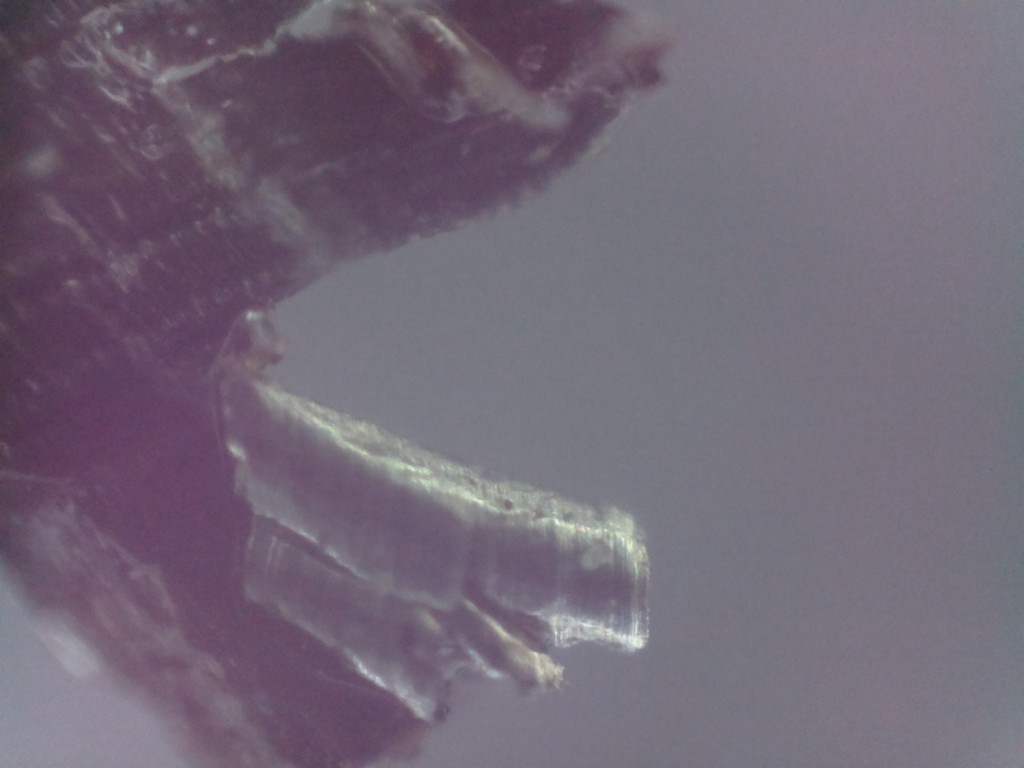

5. Machining fragments are a job for a detective. Where did they come from? You would be surprised how accurate you can be. Drilling, turning or milling?

The shape of the chip is quite distinctive on a microscopic level. You can even see whether the drill was sharp or whether it has been tearing the material. You would then check another piece of contamination for being magnetic or not. Can you “see” steel or aluminium alloy by its colour?

To an extent. If you are lucky enough to see steel, you will see a dull grey. Aluminium alloy, that shines. Sometimes you are not so lucky. Keep an open mind until you have had a good look on the ioLight.

Figure 5- Machining Fragment

Figure 5- Machining Fragment

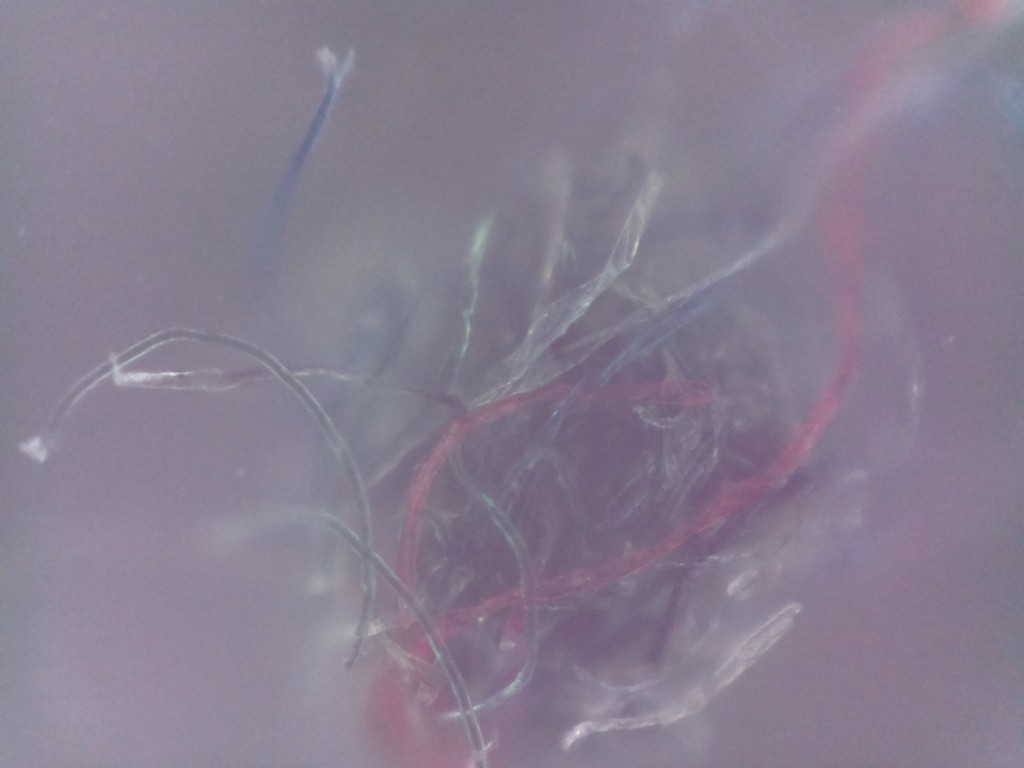

6. Synthetic fibres from fleeces and other garments. These get everywhere. You can identify them very easily and they are distinctly different from human hairs. One of our customers was even foolish enough to think that a bench covered in carpet tiles was a good environment. The fibre contamination was monumental.

Figure 6- Clothes fibres

Figure 6- Clothes fibres

You have to acknowledge that the atmosphere is truly filthy and unless you are assembling in a clean area, you need to manage this risk. We have blogged before on the cleanliness battle in the hydraulic assembly shop on https://sarum-hydraulics.co.uk/blog/hydraulic-cleanliness/.

Look at our own Micropac hydraulics on www.sarum-hydraulics.co.uk.

Visit ioLight on www.iolight.co.uk.

Leave A Comment