Aerospace Service Hydraulic Equipment and Ground Support Equipment (GSE)

Micropac manual hydraulics is used in many aerospace service hydraulics and ground support equipment (GSE) applications.

Sarum Hydraulics has long experience of our Micropac equipment being used for Ground Support Equipment (GSE.) and associated applications. It is non-flying and not FAA/CAA approved.

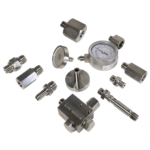

Our MP series pressure test , filling and charging pumps can be supplied as compact carry arounds in stainless steel or lightweight anodised alloy. Larger volume reservoirs can be fitted with our own very compact and neat two wheel cart with hose brackets for easy stowage. Large reservoirs can be mounted on our four wheel pull-around trolley.

We have long experience of aerospace fluids. Pumps are supplied in the optimum materials and with the correct seals. Our equipment is very widely used for dispensing and testing on Skydrol and similar aerospace phosphate esters. Our MI dispensers actually dispense directly from the manufacturer drum or can for clean operation and reduced spillage.

Hoses and specialist fittings are our speciality.

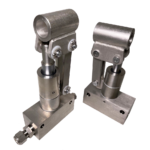

We have long experience of more specialist GSE equipment using our Micropac pumps. For example, our 151000100 has provided an equivalent to the 856A1084 G04 VGV / VSV test unit for operators worldwide for over 30 years. Our equivalent unit is offered to service the various G0 versions and also the 2C6395 unit which is fairly similar.

Our various products are most often used for:

– testing, both pressure testing and functional testing

– calibration and setting pressures

– filling and dispensing

– building into a more complex system.

However, they are not FAA or CAA approved for flying and are limited to the hydraulics in Ground Support Equipment or in aircraft production.

Skydrol

We have considerable expertise on aerospace applications, fluids and specialist requirements. In particular, we have long standing expertise on Eastman ‘Skydrol’ fluid hydraulics. Read our white paper “what is skydrol and what is it used for?” for our experience in working with this fluid plus specifying metals, plastics and finishes in design for operation on this medium.

Our Micropac MI series pumps can be used for dispensing Skydrol fluid direct from the manufacturer’s cans or drums to maintain cleanliness. The pump unit forms a neat carrier for the drum, allowing it to be wheeled or carried around then stored. Alternatively, the fluid can be poured into one of our MP series 10, 20 or 50 litre two wheel trolley units and this unit forming your Skydrol dispenser.

If you require a hand pump piped into a system, look at our MW-3 series stainless steel hand pumps. These are also available as pumps with optional fixed reservoirs within this range. Reservoirs range from 2.5 litres to 50 litres.

If you require a carry-around pump/reservoir for your filling, testing or servicing application, look at our MP-3 series. Two wheel trolley units are available for 20 and 50 litre reservoirs.

Micropac 20 litre MP series Skydrol trolley

The anodised alloy and stainless hand pumps will also operate on Skydrol. Talk to us to select a pump for your application.

Our MB series drum pump and low pressure hand pump offer 100cc/double stroke to 50 bar and is manufactured in 100% 316 stainless and polymer.

If you require a pure component hand pump for a more complex system, our PPS pump builder unit is available in three models up to 400 bar. It is a very compact component hand pump in 100% 316 stainless and polymer with inlet and outlet check valves. Connections are using Swagelok double ferrule tube fittings or a range of male and female threaded adaptors. You will specify your other components such as a release needle valve or relief valve from catalogues such as Swagelok.

Our Micropac PSP has a wide customer base within skydrol GSE equipment. It offers two speed operation to 1000 bar with wetted parts as anodised alloy and stainless steel. It has interchangeability with the 89mm square industry standards such as the Hydrapak, HMP & MHX (Trade marks acknowledged.) Peroxide cured EPDM seals are a modest cost and short lead time, as the unit was designed to allow easy upgrade.

Other Aerospace media

Micropac manual hydraulic pumps are used in many other applications using mineral oil based applications and increasingly synthetic fluids. We are experts on seal compatibility and can also offer cost effective solutions for low temperature ground support equipment.

Our Pumps for Aerospace

We have a wide range of pumps. The units that have typically found wider application in Aerospace are detailed below. Always check on the exact fluid and temperature range in case special seals are required. We are always pleased to discuss any new applications for any of our units. Our equipment is high quality and fully serviceable, offering a long service life.

Our Micropac MP Pressure Test Pump with integral reservoir is widely used for pressure testing, charging and filling on mineral oil based and synthetic aerospace fluids. The range of portable reservoirs includes two wheel trolley units with hose stowage.

Our Micropac MW series offers a range of pumps suitable for hydraulic systems. For demanding applications for highly corrosive environments or aggressive fluids specify the MW-3 316 Stainless Steel or for a lower cost and mass option look at the MW-A Aluminium Alloy unit. A full range of fixed and portable reservoirs are compatible with these units from our Micropac MR Reservoirs range.

Our Micropac MD series two speed hand pump offers pressures up to 1000 bar and 316 stainless construction. Fixed and portable reservoirs are available. This high quality unit has found application for testing on multiple media and also in actuation where the two speed operation will reduce the number of hand strokes to cycle an actuator in manual mode.

Our PPS pump offer 100% 316 and pressures up to 400 bar as a component hand pump only with just inlet and outlet check valves.

Our MT series cartridge pump has application on manifold based systems used for testing or handling systems. A range of materials and seal options are available.

Our Micropac PSP has a wide customer base within GSE equipment. It offers two speed operation to 700 bar with wetted parts as anodised alloy and stainless steel. It has interchangeability with the 89mm square industry standards such as the Hydrapak, HMP & MHX (Trade marks acknowledged.)

Our 151000100 VGV Actuator Pressure Test Unit has provided an equivalent to the 856A1084 G04 vgv/vsv test unit for operators worldwide for over 30 years. Our equivalent unit is offered to service the various G0 versions and also the 2C6395 unit which is fairly similar.